Euromax Resources Ltd. 5 June 2014 (TSX-V: EOX): (“Euromax” or the “Company”) is pleased to announce the results of the Pre-Feasibility Study (“PFS”), including a maiden Mineral Reserve, for its 100% owned Ilovica gold-copper porphyry project in Macedonia. With an NPV of US$675 million the PFS demonstrates the economic robustness of the Ilovica Project (the “Project”), building upon the significantly increased Mineral Resource announced 3 December 2013, as well as incorporating costs based on supplier quotes and engineering studies carried out to at least pre-feasibility industry standards.

PFS Highlights (based on US$1,250/oz Au and US$3.00/lb Cu)

- Maiden Total Probable Reserve of 225 million tonnes containing:

- 2.45 million ounces of gold

- 905 million pounds (411 thousand tonnes) of copper

- Total Sulphide Probable Reserve of 209 million tonnes at an average grade of 0.34 g/t Au and 0.20% Cu

- Total Oxide Probable Reserve of 16 million tonnes at 0.33 g/t Au

- Throughput of 10 million tonnes per annum and mine life of 23 years

- Conventional open pit with strip ratio of 0.7:1

- Average process recoveries of 86.5% gold and 84% copper

- Average annual payable production of 95,000 oz gold and 16,000 tonnes of copper

- World Gold Council defined Adjusted Operating Cash Costs of US$216/oz and All-In Costs of US$334/oz*

- Pre-tax NPV(5%) of US$675 million and Post-tax NPV(5%) of US$558 million

- Pre-tax IRR of 18.6% and Post-tax IRR of 16.5%

- Initial Capex US$502 million including contingency

- Distributable post-tax net cash flow of US$1.2 billion after capex

The PFS was produced by the following experts who worked with the Company’s technical team:

- Tetra Tech – Geology, Resources, Mineral Processing and Engineering, Infrastructure, Hydrolgeology, Hydrology;

- ACA Howe International – Mining and Reserves, Mine Infrastructure;

- Faculty of Civil Engineering from St. Cyril and Methodius University of Skopje – Tailings

A detailed breakdown and discussion of the PFS results can be found in the Appendix and an independent NI 43-101 compliant technical report will be filed on SEDAR and the Company’s website within 45 days of this announcement.

Project Advancement & Financing

The Company has established a Technical Advisory Committee (“TAC”) of leading experts in their fields who will form the core of the owner’s team to ensure efficient project execution and who will oversee the progression of the Project through full Feasibility Study/Front End Engineering Design (“FS/FEED”) and into construction.

The recently announced sale of the Company’s Bulgarian assets, the establishment of a Balkan focused exploration services company and corporate streamlining, has freed up management and financial resources to be wholly dedicated to the development of Ilovica.

The Company is implementing its finance plan in two phases: Phase 1 to cover the FS/FEED costs and Phase 2 for the financing of the construction capex. Confidentiality agreements have been executed and due diligence is underway with several potential financing partners, contemplating an asset-based financing for Phase 1 to the start of construction.

Financing structures being considered include metal streaming and royalty arrangements. The agreed structure will be designed to ensure minimal shareholder dilution, whilst at the same time leveraging the asset value, so as to neatly dovetail into the Phase 2 financing of construction scheduled to commence in 2016. Further, with the completion of the PFS, the Company is now able to engage with certain banking counterparties to initiate due diligence for a Project Financing to fund Phase 2, the construction.

Commenting on the results of the PFS, Pat Forward, Chief Operating Officer, said: “Following the work carried out in 2013 to define the expanded Mineral Resource, we are pleased that our PFS on the Ilovica Project has defined a financially attractive operation based on a robust study, more than justifying the next steps in project development. We are now in an excellent position to build on this as we continue with our full feasibility work and then the front end engineering and continue to establish our owner’s team to fulfil our ambition to build and operate the first major modern mine in Macedonia.”

Commenting on the results of the PFS, Steve Sharpe, President & CEO, said: “Despite incredibly challenging mining equity markets that have seen a decline in the market value of our Company despite the significant increase in the asset value of Ilovica, it is particularly rewarding to be able to now publicly demonstrate the exceptionally robust economics of the Ilovica Project. This is a massively important project for Macedonia, and as one of the few permitted mining projects in Europe, will dramatically enhance the economic profile of the country. The overwhelming local, national, and indeed supranational support for the project places us in the enviable position of certainty of development. Our immediate task is for the management team to deliver the implementation of a minimally dilutive financing package and the management of the DFS/FEED process to ensure the start of construction in 2016 and first production in 2017. These areas are exactly where our strongest skill sets and track records lie.”

Conference Call

The Company will be hosting a conference call and question and answer session to discuss the results of the PFS on Friday 6th June, 2014 at 10 am EST / 3pm BST. A new presentation will be uploaded to the Company’s website in advance of the call. To participate in the call, please dial:

United Kingdom: 020 3139 4830 orUK Toll-Free Number: 0808 237 0030

Canada: 1 514 841 2196 orCanada Toll-Free: 1 866 404 5783

United States: 1 718 873 9077 orUS Toll-Free Number: 1 866 928 7517

Participant pin code: 76848541#

Notes:

* Adjusted Operating Cash Costs and All-In Costs as defined by the World Gold Council which assumes copper as a by-product and includes US$1.8M corporate G&A.

Qualified Person

Mr Patrick Forward, FIMMM, a Qualified Person under National Instrument 43-101 Standards of Disclosure for Mineral Projects of the Canadian Securities Administrators and COO of the Company, reviewed and approved the scientific or technical disclosure in this release and has verified the data included.

About Euromax Resources Ltd.

Euromax is a Canadian exploration and development Company with gold and base metal assets in Macedonia and Serbia and an exploration services company in Bulgaria. We are focused on developing mineral resources in Southeastern Europe, with the objective of becoming a world-class mining company in the region. Our strength lies in our corporate and local management and technical expertise in Macedonia, Bulgaria and Serbia.

APPENDIX A

Geology & Resources – The Ilovica porphyry system is located in southeast Macedonia, within the tertiary belt associated with the Carpathian arc. The intrusive is about 1.5 km in diameter and comprises a dacite-granodiorite plug, emplaced along the northeastern border of the Strumica graben. Mineralisation is typical porphyry style veining, most intense within the potassic zone. The mineralisation shows good continuity and homogeneity that lends itself well to bulk-mining methods. The current pit-constrained Mineral Resources for the property, details of which were announced on the 3 December 2013 can be summarised as follows:

Notes:

- Dollar equivalent cut-off based upon the following calculation Dollar Eq. = (Au * recovery * price) + (Cu * recovery * price), using the following inputs:

- Au process recovery in oxide 86% based on early test work

- Cu process recovery in oxide 0% based on early test work

- Cu process recovery in fresh 85% based on early test work

- Au process recovery in fresh 65% based on early test work

- Spot metal prices effective 19 August 2013 (Au = US$1,366/oz, Cu = US$3.30/ lb)

- Resource cut-off of US$16 used for sulphide material

- Resource cut-off of US$8 used for oxide material

- Numbers may not add exactly due to rounding

- Mineral resources that are not mineral reserves do not have demonstrated economic viability. The estimate of mineral resources may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues. The mineral resources in this news release were estimated using current Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) standards, definitions and guidelines.

- For additional information on key assumptions, parameters and methods used to estimate the mineral resources and mineral reserves, including quality assurance measures and other technical information in respect of Ilovica, please refer to our technical report entitled “Resource Update on the Ilovica Project, Macedonia” and with an effective date of 27 November 2013.

Mining & Reserves – Mining is planned via conventional open pit methods using a large scale mining fleet that enables bulk-mining at a rate of 10 million tonnes a year. The good continuity of grade in the main mineralised areas enables mining to be carried out at a low average strip-ratio of 0.7:1. Ore will be crushed with a gyratory crusher at the pit exit before being transported to the mill by conveyor. With the completion of the PFS, the Company is pleased to announce a new Mineral Reserve for the project which is summarised in the table below:

Processing – Ore will be milled by SAG and Ball mills and then processed by a concentrator using conventional flotation to produce a copper-gold concentrate with the flotation tailings being re-treated to recover further gold doré on site. Test work conducted by SGS Mineral Services in the UK has confirmed an overall process recovery of 86.5% for gold and 84% for copper and the PFS study is based on shipping concentrate to the Pirdop smelter in Bulgaria.

Tailings – Waste rock from the open pit will be used to construct the tailings embankment. Whilst the mining operation does not require significant pre-stripping, some 10Mt of inert waste rock mining has been brought forward in schedule to the construction period for a starter dam. The dam will then be raised over the mine life using the down-stream construction approach. A crusher will be located at the embankment site in order to allow engineered fill to be placed on the upstream face, which will also be lined. The plant site is situated above the tailings facility and thickeners will be utilised to produce a thickened tailings to be pumped to the facility below.

Infrastructure – A site plan has been developed covering haul roads, workshops, access roads from the National Highway, water balance pumping scheme and power infrastructure from the main 110kV supply some 7 kilometres from the plant have been developed for the project using Macedonian and European rates.

Capital Costs – Capital Cost estimates were developed using quotations for mobile and plant equipment and engineering studies carried out to at least pre-feasibility industry standards. The Capital Cost Summary is include in the table below:

Operating Costs – Operating costs were derived from quotations for fuel, power, consumables and reagents from suppliers in Macedonia and internationally where local costs were not verifiable and local and international labour costs as appropriate. The Operating Costs estimate is included in the table below:

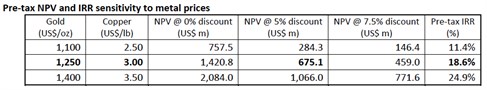

Financial Analysis – The PFS demonstrates a robust NPV at a 5% discount of US$675 million with an IRR of 19% before tax and an after tax NPV at a 5% discount of US$558 million and after tax IRR 16%. The following table illustrates the sensitivity to changes to the calculated IRR and NPV at 0%, 5% and 7.5% discount rates at various gold and copper prices. No assurance or guarantee is provided that the calculated IRR or NPV values will be achieved.